Tips for PCB Storage with different surface finishing

Tips for PCB Storage with different surface finishing

PCB design and development can be quite intensive, which means you invest a lot of your time and money into it. If you wish to enjoy the full benefits and return on investment, you need to take protective actions both during and after production to make sure the shelf life of PCBs and their components is guaranteed. That’s where PCB storage guidelines come in and why it’s so important to follow them.

The Essentials of Proper PCB Handling

Proper PCB handling is something that you need to consider at each step of the manufacturing process.Direct handling of PCBs should be kept to a minimum, which means your personnel must transport them on racks or tray carts rather than by hand.

Whenever PCBs need to be held directly, it’s important to take them gently by the edges and wear clean gloves if possible. Protective bags also need to be used when transferring PCBs from one station to the other, which will reduce FOD (foreign object debris) contamination.

The people handling PCBs also need to refrain from using lotions or other products that may compromise the quality of the products and the handling areas should be free of items that produce static electricity, such as carpets.

1. Surface Finish During Fabrication

After bare boards are fabricated, they may require temporary storage before they are assembled. During this period, you must protect PCBs against contamination and oxidation by using an appropriate surface finish during fabrication. Each surface finish also has a recommended shelf life which we will go into later in this article.

2. Whenever Possible, Use Components Not Sensitive to Moisture

SMD components that are not sensitive to moisture will have a virtually limitless lifetime if they’re stored in environments with ≤85% relative humidity and temperatures ≤ 30°C (86°F). Components that are sensitive to moisture will last a day to a year before assembly. So, whenever possible, use non-moisture sensitive components.

3. Store PCBs in Moisture Barrier Bags (MBB)

Moisture barrier bags will enclose your PCBs in a plastic or metallic shield that will keep your boards moisture free. These bags feature film layers that are specialized and will control moisture absorption rate. An additional benefit is that MBBs protect your PCBs from static. All your PCBs must be stored in moisture barrier bags with desiccant pouches to keep moisture and humidity at bay. They also must be dry and vacuum-sealed to protect the PCBs from ESD and corrosion.

4. Maintain a Controlled Environment

PCBs should always be stored in a controlled environment, meaning extreme temperature variations need to be avoided at all costs. This is important to maintain not only during storage but also during shipping. As mentioned above, the environment should be kept at 85% RH and temperature ≤ 30°C (86°F).Overall, you need to make sure you have quality suppliers that follow these protocols. If not, encourage CMs to follow storage standards, ensure PCB assembly cleanliness is strict, store and ship PCBs and PCBAs in dry packets, and do whatever else you can to make sure your boards and products are of the highest quality.

PCB Shelf Life

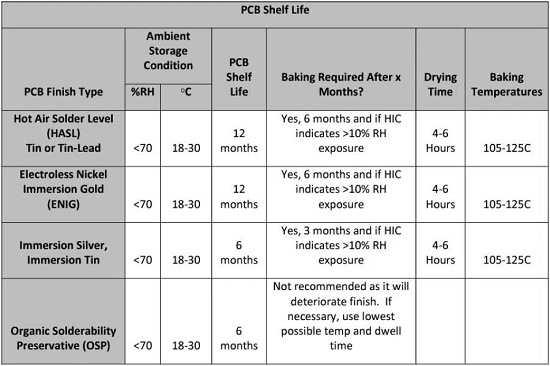

Each surface finish has a different PCB storage shelf life. In general, the different recommendations for each are as follows:

1.Tin or Tin-Lead HASL, Immersion Gold = 1 year (also shown in Table 1 below)

2.Immersion Silver, Immersion Tin, OSP = 6 months (also shown in Table 1 below)

3.PCBs that are out of Shelf Life specified in i & ii above are to be scrapped or baked. This is due to the moisture absorption of the material and the increased susceptibility to delamination during assembly of the PCB. iv. Table 1 outlines the recommended shelf life, storage and bake conditions for PCB (for further details, refer to IPC-1601).

Conclusion

Proper PCB storage and handling is key to a successful operation. It increases your product’s chances of success and allows you to sleep knowing there will be one less issue to worry about during manufacturing. Hopetimepcb has strict PCB handling and storage guidelines. We make sure to take care of our customer’s parts and that PCB assembly will go off without a hitch. Please reach out to our team if you have any further questions about PCB storage or if you have a product we can help build.

Refer to IPC-1601A for IPC’s official document on PCB Storage

Click here:Most common used PCB surface finishing comparison

Click here:Advantage and disadvantage for PCB common surface treatment

Click here:Introduction for Surface finish choices

Click here:Tips for PCB Storage with different surface finishing

Click here:PCB Final surface finish comparison

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry