What causes PCB bow and twist?

What causes PCB bow and twist?

There are several factors that contribute to the likelihood that a design may bow or twist. Some of the most common are:

1.Uneven Copper Distribution

2.Unbalanced Stack Up

3.Pre-Preg Materials Arranged Incorrectly

4.Mixed Material Types

5.Finished Thickness

6.Moisture

7.Rapid Heating During Assembly

8.Assembly Conveyor Setup

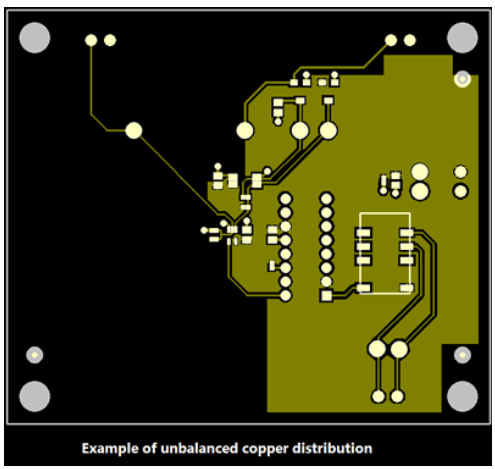

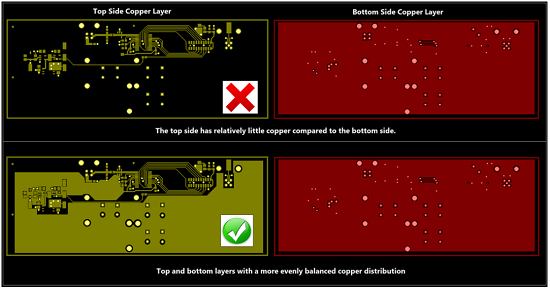

Uneven Copper Distribution

Copper absorbs heat more readily than the PCB laminate. Copper has a comparatively high coefficient of thermal expansion (CTE). If your design has large copper planes or if there are large open spaces with no copper, the copper imbalance may cause the board to flex when heated. Always try to evenly distribute copper across a layer as much as possible. Sometimes copper thieving will be added as necessary to help minimize the likelihood your design will bow or twist.Also consider the copper distribution on each layer as it relates to the other layers in your design. Issues can arise with your design is one layer has a lot more copper than the others.

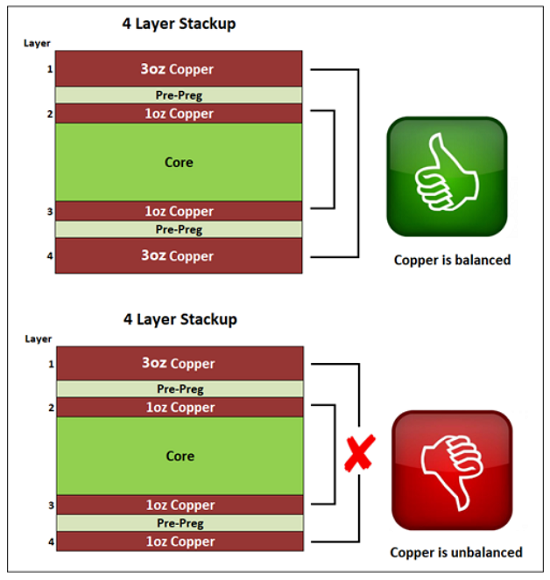

Unbalanced Stack Up

It's a good idea to balance the copper weights (copper thickness) used on each layer in a multilayer design. For example, when designing a 4 layer board, specifying 3oz copper on only one layer and 1oz on the remaining layers would greatly increase the probability of warping.

Pre-Preg Materials Arranged Incorrectly

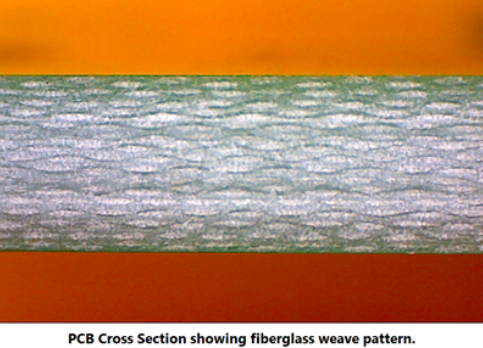

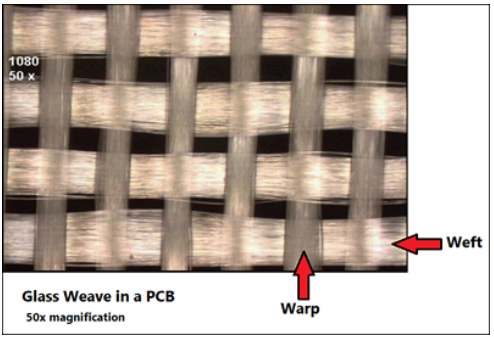

The vast majority of printed circuit board materials in use today are manufactured from an epoxy impregnated woven fiberglass. The weaving process orients the fiberglass strands in 2 directions, perpendicular to each other.

The glass strands laid in the primary direction are under slightly more tension and are called the warp. The strands that are woven in between the warp are called the weft. Before the lamination process, the direction of the warp and weft (grain) should alternate between dielectric layers to reduce the potential the laminate may bow or twist. If every layer is oriented with the warp in the same direction, this tension can compound and result in bow or twist.

The picture shows how fiberglass strands are woven before being impregnated with epoxy resin.

There are More factors cause the PCB bow and twist,as mentioned above:Mixed Material Types;Finished Thickness;Moisture;Rapid Heating During Assembly;Assembly Conveyor

Click at here:What Is PCB Bow and Twist?

What causes PCB bow and twist?-Uneven Copper Distribution

What causes PCB bow and twist?-Unbalanced Stack Up

What causes PCB bow and twist?-Pre-Preg Materials Arranged Incorrectly

What causes PCB bow and twist?-Mixed Material Types

What causes PCB bow and twist?-Finished Thickness

What causes PCB bow and twist?-Moisture

What causes PCB bow and twist?-Rapid Heating During Assembly

What causes PCB bow and twist?-Assembly Conveyor Setup

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry