Introduction for ROGERS RO4350B

Introduction for Rogers RO4350B

Rogers RO4350B materials are proprietary woven glass reinforced hydrocarbon/ceramics with electrical performance close to PTFE/woven glass and the manufacturability of epoxy/ glass.RO4350B laminates provide tight control on dielectric constant (Dk) and maintain low loss while utilizing the same processing method as standard epoxy/glass. Available at a fraction of the cost of conventional microwave laminates, RO4350B laminates do not require the special through-hole treatments or handling procedures as PTFE based materials. These materials are UL 94 V-0 rated for active devices and high power RF designs.

Features

• Dk of 3.48 +/- 0.05

• Dissipation factor of 0.0037 at 10 GHz

• Low Z-axis coefficient of thermal expansion at 32 ppm/°C

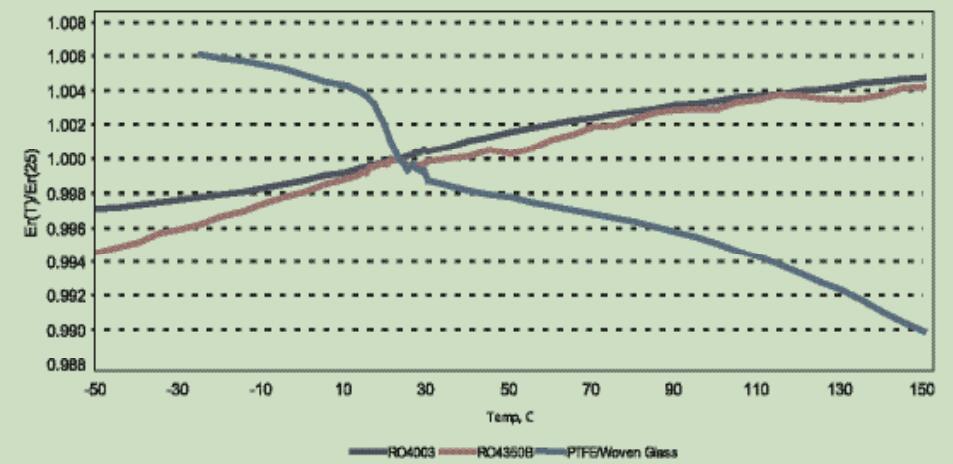

Chart 1: RO4000 Series Materials Dielectric Constant vs. Temperature

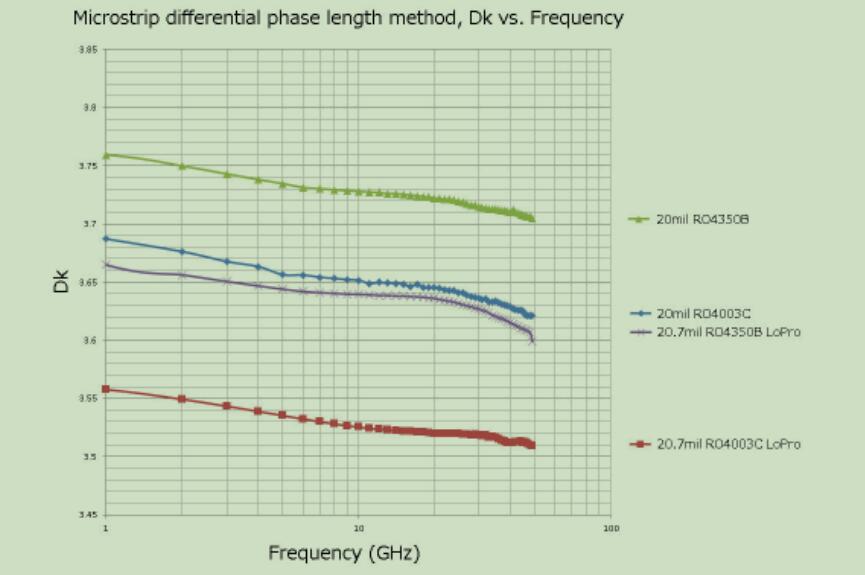

Chart 2: RO4000 Series Materials Dielectric Constant vs. Frequency

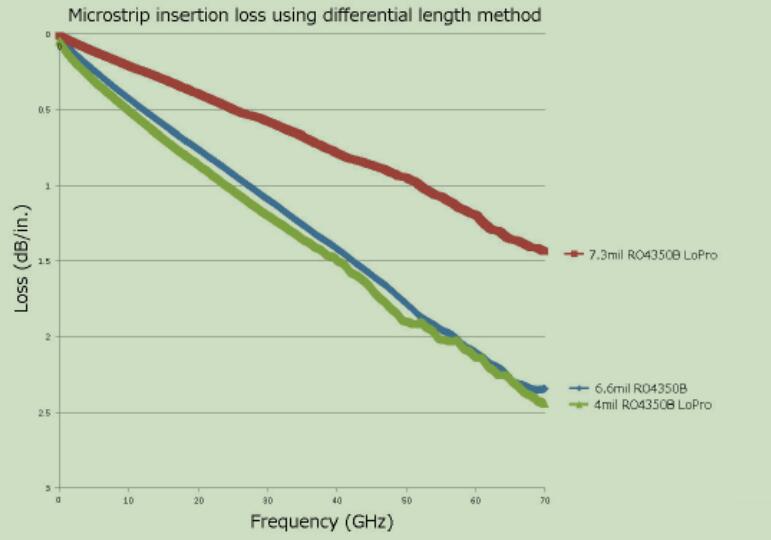

Chart 3: Microstrip Insertion Loss

Benefits

• Processes like FR-4 at lower fabrication cost

• Competitively priced

• Excellent dimensional stability

Applications

• Backhaul radios

• Communications systems

• Computing

• IP Infrastructure

• Power Amplifiers

• Small Cells / DAS

• Test & Measurement

Some of the typical applications which significantly benefits from RO4350B include:

1.Global comunications systems

2.Complex multi-layer and highly reliable circuits

3.Wireless communication equipment

4.Couplers

5.Microwave point to point connections

6.Automotive radar and sensors

7.LNB for live satellites

8.Power amplifiers

9.3G and 4G antenna

10.Power amplifiers

11.Power dividers

12.Trunk amplifiers

13.RF transmitter

14.Multi-coupler antenna

15.RF identification

16.Spread spectrum communication systems

17.A cellular base station and microstrip antennas

18.LNB’s for direct broadcast satellites

19.Relay stations

20.Variocoupler

21.RF switches ect.

What is the temperature rise estimation for Rogers RO4350B circuit board?

You can determine the temperature rise estimate of RO4350B laminate by conducting a series of calculations under the following assumptions:

1.The ground planes receive all the heat generated by RF power or current through Z-direction generation.

2.The complete loss of RF power insertion is regarded as conductor trace generated heat.

3.It has reached a steady-state

4.The ground plane maintains a uniform temperature,and a consistent rise in conductor metal temperature is evident.

When subjected to similar power levels and frequencies,FR-4 shows a high rise in temperature of about +84°C which RO4350B only exhibits a +56°C rise above average room temperature.

Which surface finishing can be applied with the RO4350B circuit board?

PCB surface finishing is coating applied between the bard board and the components to protect exposed copper circuity and enhance the solderability.

Below are some of the common choosed surface finishing:

- HASL-hot air solder levelling

It is widely used surface coating technique

it involves immersing the circuit board into molten lead and tin alloys then getting rid of excess solder by blowing hot air across the board’s surfaces(Air Knives).

- ENIG-Electroless Nickel Immersion Gold

It is a two-layered metallic coating.Nickel provides the barrier copper and offers a surface for soldering the components.

The gold layer provides low contact resistance and protects Nickel in storage.

- ENEPIG-Electroless Nickel Electroless Palladium Immersion Gold

The coating constitutes three layers of metallic coating of Nickel,Palladium,and gold.Unlike other coatings,ENEPIG is bondable.

It outperforms most of the coating types after assembly resistance to corrosion and is best suited for high-frequency applications that do not have sufficient spacing.

- Immersion Tin

This kind of finishing applies metallic finish over the underlying copper through a chemical displacement reaction.It protects the copper throughout its service life.

- Organic Coating

It is a water-based finishing techinique that uses organic compounds suitable used for copper pads.It preferable binds to copper,forming an organometallic layer that protects it before soldering.

It preserves the underlying copper through the conveyorized process involving applying a thin material layer over the exposed copper surface.

- Immersion Silver

The finishing constitutes sub-micron coating with almost pure silver through replacement reaction.Sometimes it can contain organic matter that prevents corrosion,silver to silver migration,and tarnishing.

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Link

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry