Products >> THT Assembly/Through Hole Assembly Technology

Through Hole Assembly Technology

PCBs started as a one-sided board, then two-sided, until multi-layer boards became popular. Through-hole mounting was the standard practice until surface mount technology (SMT) became popular in the 1980s.

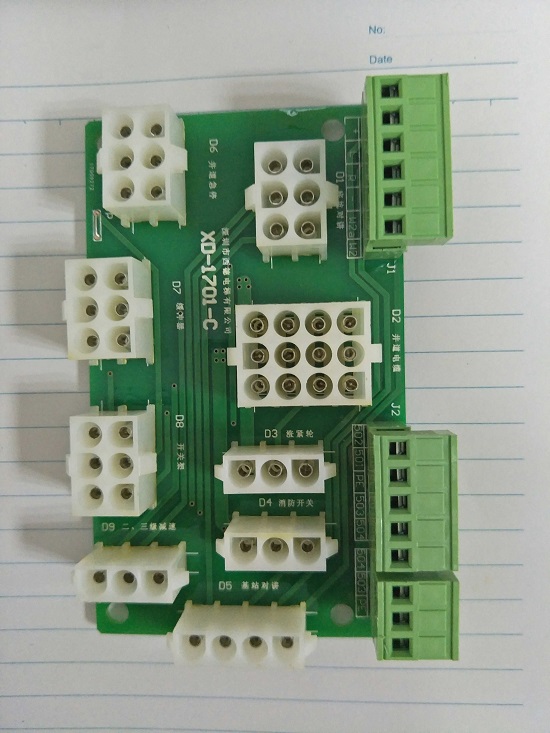

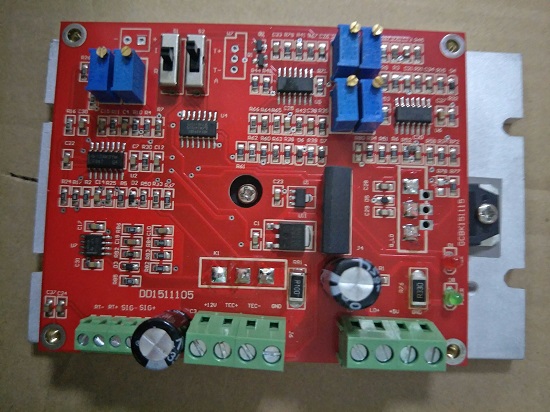

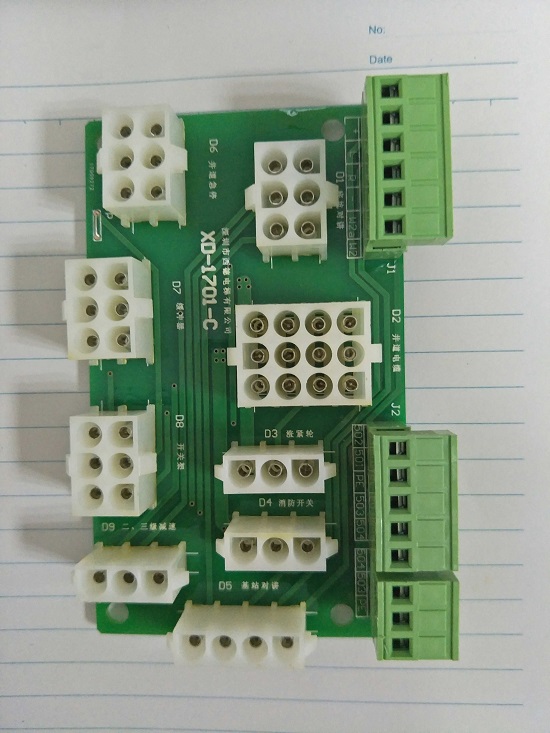

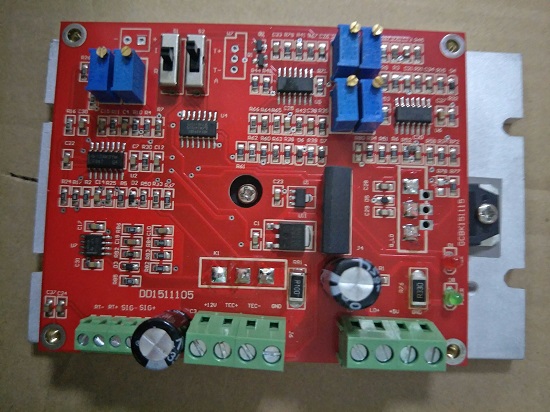

Through Hole technology is a method for constructing electronic circuits in which the pin-through hole (PTH) components are inserted through holes drilled into printed circuit boards (PCBs). The ends, or leads, are then affixed to pads on the opposite side with molten metal solder using wave soldering or reflow soldering equipment. This process is also called through hole assembly.

Through Hole technology replaced early electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology became popular in the late 1980s, every component on a typical PCB was a through hole component.

While through hole mounting provides stronger mechanical bonds than surface-mount technology techniques, the additional drilling required makes the boards more expensive to produce. It also limits the available routing area for signal traces on multilayer boards since the holes must pass through all layers to the opposite side. For these reasons, through hole mounting is normally reserved for bulkier components such as electrolytic capacitors or semiconductors in large packages that require additional mounting strength to endure physical stress.

The advent of surface mount technology was initially thought to have made through-hole technology obsolete, but it proved to be a very resilient technology because of its distinct advantages and niche reliability.

Advantages of Through-Hole Technology

Through-hole components proved to be more reliable in products requiring stronger connections between the layers. Through-hole component leads are capable of withstanding a lot more environmental stress because they run through the board while SMT components are only secured by the solder of the board’s surface. This advantage makes through-hole technology the preferred process in aerospace and military products that endure high temperatures, extreme accelerations, and collisions. Through-hole technology is also used in applications that require testing and prototyping because of the manual replacement and adjustment capabilities.

Through-hole technology’s need for strong mechanical bonds makes the boards more expensive than SMT boards. That is why through-hole technology is now reserved mostly for heavier or bulkier components such as semiconductors or electrolytic capacitors in larger packages that need more mounting strength. They are also popular for elements like plug connectors that need a lot of muscle for reinforcement.

Most design engineers and manufacturers, including EMS Solutions, prefer the reliable through-hole technology to SMT when they are prototyping because through-hole can be used with breadboard sockets. Through-hole, however, is not appropriate for high frequency or high-speed designs that require minimal stray capacitance and inductance in wire leads.In addition, through-hole is not recommended for ultra-compact designs, which require SMT construction, even in the prototype stage.

Through Hole technology is a method for constructing electronic circuits in which the pin-through hole (PTH) components are inserted through holes drilled into printed circuit boards (PCBs). The ends, or leads, are then affixed to pads on the opposite side with molten metal solder using wave soldering or reflow soldering equipment. This process is also called through hole assembly.

Through Hole technology replaced early electronics assembly techniques such as point-to-point construction. From the second generation of computers in the 1950s until surface-mount technology became popular in the late 1980s, every component on a typical PCB was a through hole component.

While through hole mounting provides stronger mechanical bonds than surface-mount technology techniques, the additional drilling required makes the boards more expensive to produce. It also limits the available routing area for signal traces on multilayer boards since the holes must pass through all layers to the opposite side. For these reasons, through hole mounting is normally reserved for bulkier components such as electrolytic capacitors or semiconductors in large packages that require additional mounting strength to endure physical stress.

The advent of surface mount technology was initially thought to have made through-hole technology obsolete, but it proved to be a very resilient technology because of its distinct advantages and niche reliability.

Advantages of Through-Hole Technology

Through-hole components proved to be more reliable in products requiring stronger connections between the layers. Through-hole component leads are capable of withstanding a lot more environmental stress because they run through the board while SMT components are only secured by the solder of the board’s surface. This advantage makes through-hole technology the preferred process in aerospace and military products that endure high temperatures, extreme accelerations, and collisions. Through-hole technology is also used in applications that require testing and prototyping because of the manual replacement and adjustment capabilities.

Through-hole technology’s need for strong mechanical bonds makes the boards more expensive than SMT boards. That is why through-hole technology is now reserved mostly for heavier or bulkier components such as semiconductors or electrolytic capacitors in larger packages that need more mounting strength. They are also popular for elements like plug connectors that need a lot of muscle for reinforcement.

Most design engineers and manufacturers, including EMS Solutions, prefer the reliable through-hole technology to SMT when they are prototyping because through-hole can be used with breadboard sockets. Through-hole, however, is not appropriate for high frequency or high-speed designs that require minimal stray capacitance and inductance in wire leads.In addition, through-hole is not recommended for ultra-compact designs, which require SMT construction, even in the prototype stage.

Products Category

- PCB manufacturing

- PCB Assembly

- BGA Assembly

- THT Assembly/Through Hole Assembly Technology

- SMT Assembly

- Mixed PCB Assembly in Electronic PCBA

- Single sided PCB assembly

- Double sided PCB assembly

- Rigid-Flex Assembly

- COB Bonding Manufacturing

- Components sourcing for PCB Assembly

- SMT Stencils

- Box build assembly

- PCB engineer reverse

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 17 floor,Block B,Phoenix Century Garden,Fuyong Town, Baoan district,Shenzhen China 518103

Link

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry