What is heatsink paste in PCB?

What is heatsink paste in PCB?

Introduction

Heatsink paste is a paste that consists of a special polymer which is filled with finely dispersed solid particles.The dispersed solid particles provide the thermal conductivity needed for the paste to act as a heatsink.

Applications

Heatsink paste can be used to create printed heatsinks of various geometric shapes directly on a PCB as an alternative to metal-foil heatsinks or externally fixed heatsinks.

Heatsink paste is used as an interface between heat sinks and heat sources. An example of a heat source is a LED component, that often creates and suffers from heat. So it is imperative to lead the heat away from the component. This is only possible by using IMS boards (ALU) and mount it on an heat sink using heat sink paste.

With a more complex layout, one can no longer rely on the single sided IMS but will need a double sided board. Heat sink paste allows to do that. Under the specific component we place a via and fill it with heat sink paste or thermal conductive and electrical insulated paste. The paste in the vias will lead the heat through the vias to the other side of the board. Here it comes in contact with a heat sink. We often use his type of technique for pulsing LED (examples are warning lights on emergency vehicles).

Example

Generating Data Output

Always clearly indicate on which side of the PCB the heatsink paste is to be applied.This can be on one side or on both sides.When generating output please include the board outline.This is best done using a small line – e.g. 0.500mm (20mil) wide – where the center of the line is the exact board outline.We will remove this line in the actual production data we use for manufacturing your boards.

IMPORTANT

If you require Heatsink Paste on your PCB please ensure this is clearly indicated.This should be done by using correct file naming and clear buildup or layer sequence description in the Mechanical layer.

Specifications

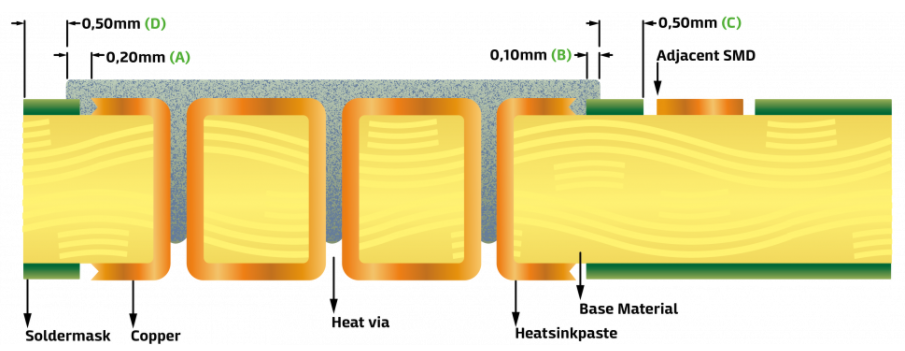

The area to where the paste is to be applied must be free of Soldermask.

-

Minimum paste on copper overlap: 0.200mm (8mil).

-

Minimum paste on Soldermask overlap: 0.100mm (4mil).

-

Minimum distance between paste and any adjacent Soldermask opening: 0.500mm (20mil).

-

Minimum distance between paste and the PCB outline (incl. NPTH holes and slots): 0.500mm (20mil).

-

Minimum paste line width: 0.300mm (12mil).

-

The recommended end size of a heat via should be between 0.800mm (32mil) and 1.200mm (48mil).

-

The recommended coating thickness of the paste is 100µm (4mil) or 200µm (8mil).

-

Heatsink paste is NOT compatible with Immersion Ag or Immersion Sn as plating finish.

Back to the technology data

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry