What is BGA?

What is BGA?

BGA is abbreviated from Ball Grid Array, a form of surface mount technology (SMT). BGA is now chosen more commonly in circuit design. BGA packages were developed due to the market demand for a more robust and convenient package to permanently mount integrated circuits with large numbers of pins. BGA allows for more interconnection pins per surface area than possible on a dual in-line or flat package. Some BGA components even mount integrated circuits with over 100 pins. To achieve this, the entire bottom of a BGA chip is largely filled with interconnection pins. By not limiting connections to the perimeter, connections under the SMD package will increase the efficiency of how space is utilized.

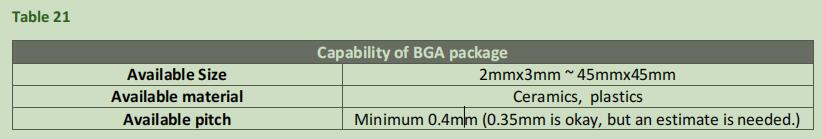

Over the years,Hopetimepcb has accumulated a vast amount of Ball Grid Array (BGA) assembly expertise and has developed a dependable process over time. Currently , our fabrication and assembly facilities use the most up to date BGA placement equipment , and we also utilize X-ray inspection equipment to verify the soldering . We have a proven record of producing BGA circuit boards with excellent yield rates and the highest quality in the electronics manufacturing industry. At Hopetimepcb,we can process BGA packages with the specifications listed in Table 21.

Our skilled workforce employs thermal profiles even for low volume prototype boards, as it is a key function in the BGA assembly process. We carefully review the circuit board files and BGA chip datasheets to make the most appropriate thermal profile for BGA assembly. Lead-free BGA circuit boards pass through a particular lead-free thermal profile to prevent ball issues, which may occur due to using a lower temperature. Alternatively, the costly leaded BGA boards are diverted through specific leaded processes to avoid high temperatures, which lead to pin shorts. We have effective quality inspection procedures in place to offer high quality services.

We possess high-tech BGA placement equipment, precise BGA assembly processes, and automated x-ray inspection (AXI) system to provide better quality BGA circuit board assembly. AXI is used to identify assembly defects; our team uses 2D x-rays to render 3D images, to verify the issues such as a circuit board broken vias in inner layers and BGA ball’s cold solder break.

Go to the PCB knowledge Page

Go to the PCB design resources page

Back to the technology data

PCB Blog

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry