Products >> PCB Assembly >> PCBA manufacturing

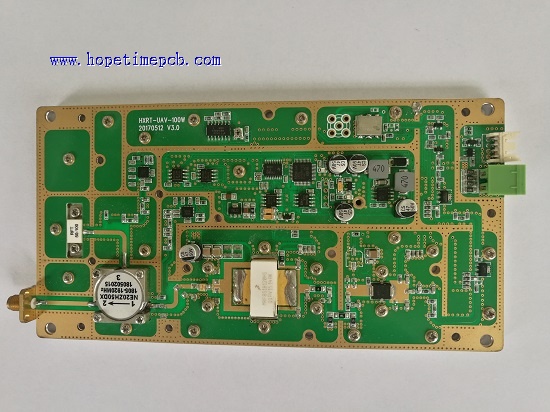

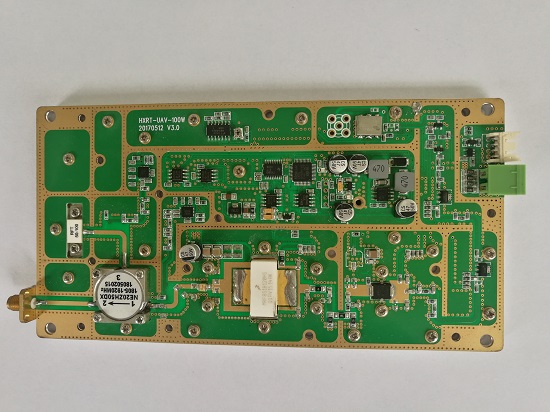

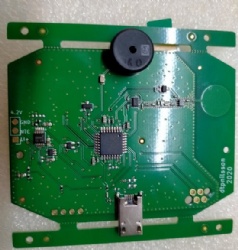

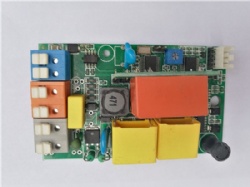

Professional immersion gold electronics PCB circuit solder board assembly

- Product No.:2020831155926

- PCB board thickness:0.6MM,0.8MM,1.0MM,1.2MM,1.6MM,2.0MM,2.4MM

- Layer count:1L.2L,4L,6L,8L,10L,12L,16L,18L,20L,24L,32L

- PCB material:FR4,CEM,ROGERS,Mixed laminate ect

- Copper thickness:0.5OZ,1OZ,1.5OZ,2OZ

- Surface treatment:HASL LF,ENIG ect

- Soldermask:Green,Black,Yellow,Blue ect

- silkscreen:White,Black

- D.K: 2.2 to 10.6

- D.F:/

- Min trace/gap:3mil

Professional immersion gold electronics PCB circuit solder board assembly

Product Description

Service:PCB Manufacturing / PCB assembly / components sourcing

Soldering is the only permanent way to fix components to a circuit.

Step 1: Collecting Materials for Soldering

--Soldering Irons

--Solder Wick - is the eraser to soldering’s pencil.

--Solder Vacuum (Solder Sucker) - is a great tool for removing solder left behind in through-holes when delsodering components.

Step 2: Preparing to Solder

--Warm Up The Iron

--Prepare A Little Space

--Thoroughly Coat The Tip In Solder

--Clean The Soldering Tip

Step 3: Soldering a PCB

--Surface Preparation

--Component Placement

--Apply Heat

--Apply Solder To The Joint

--Inspect The Joint and Cleanup

How to Ensure Solder Joint Quality?

The advantages of using AOI and X-ray inspection for solder joint quality should probably be weighed when doing the PCB assembly process.

1.Manual Visual Inspection:These should be done at virtually every stage of the assembly process and provide a quick assessment of the success of the previous step.

2.AOI(Automated Optical Inspection):This testing method is employed during fabrication and assembly and provides resolution greatly superior to visual inspection for checking solder joint volume.

3.X-Ray:This method allows for inspection of the board’s interior.As such,vias for BGAs and other packages where pads can not be seen from the surface can be examined

FAQ

*What service do you have?

Answer:We provide turnkey solution including PCB Clone,PCB fabrication,PCB Assembly,testing and other value-added service.

*What are the main products of your PCB/PCBA Services?

Answer:Medical PCBA / Telecom / Power supply / Led lighting / consumer electronics / Instrument equipment ect.

*Can we inspect quality during production?

Answer:We are welcome and transparent on each production process.

*How can you ensure our information being safe and not let third party find out our design?

Answer:We are willing to sign NDA file to follow the local law in your country and promise to keep our customers data in high confidential level.

*Do you have any minimum order quantity (MOQ)requirement?

Answer:We do not have MOQ requirement,We can support your projects stating from prototypes to mass productions.

Answer:We provide turnkey solution including PCB Clone,PCB fabrication,PCB Assembly,testing and other value-added service.

*What are the main products of your PCB/PCBA Services?

Answer:Medical PCBA / Telecom / Power supply / Led lighting / consumer electronics / Instrument equipment ect.

*Can we inspect quality during production?

Answer:We are welcome and transparent on each production process.

*How can you ensure our information being safe and not let third party find out our design?

Answer:We are willing to sign NDA file to follow the local law in your country and promise to keep our customers data in high confidential level.

*Do you have any minimum order quantity (MOQ)requirement?

Answer:We do not have MOQ requirement,We can support your projects stating from prototypes to mass productions.

Previous Product:Shenzhen Electronic Circuit Board soldering

Next Product:Surface mount circuit board SMT pcb soldering

Products Category

- PCB Design & Layout

- PCB manufacturing

- PCB Assembly

- BGA Assembly

- THT Assembly

- SMT Assembly

- Mixed PCB Assembly in Electronic PCBA

- Single sided PCB assembly

- Double sided PCB assembly

- Rigid-Flex Assembly

- COB Bonding Manufacturing

- Components sourcing for PCB Assembly

- SMT Stencils

- Box build assembly

- PCB engineer reverse

Contact Us

E-mail: [email protected]

E-mail: [email protected]

Skype: [email protected]

Whatsapp: +86 15012972502

Add: 2F, BUILDING H, WANDA INDUSTRIAL ZONE, ZHOUSHI ROAD, LANGXIN COMMUNITY,SHIYAN STREET, BAO 'AN DISTRICT, SHENZHEN, GUANGDONG, CHINA

Link

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry